Practical Lead to Gold Conversion; or an Intro to Opteron Resurrection.

It so happens that AMD resisted the informal NSA ban on the manufacture of LinuxBIOS-capable x86 CPUs slightly longer than Intel did. Or perhaps they were simply slower to succumb to Microsoft's Fritz chip decree. Whichever may be the case, vintage (pre-2011, with some caveats, inquire within) AMD Opteron motherboards are a precious and increasingly scarce non-renewable resource. Is it possible to prolong the life of these devices? And when they finally die, to bring them back to life? Turns out, in some cases, the answer is yes!

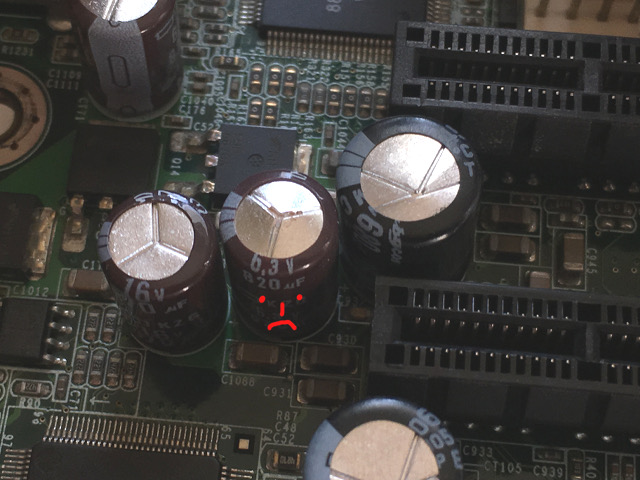

Our patient today is a Tyan S2915 with nearly 11 years of continuous service. A true champ -- but the sad day came: it would not come back up after a scheduled reboot; then, a week later, already staring at the dumpster, it deigned to switch on if "asked nicely", sporadically. The culprit, in this case, was the same as in nearly every other "smoked" mobo: aluminum electrolytic caps. But which?

One useful fact to remember: wet-electrolytic capacitors age in direct proportion to temperature.

So we take a cheap thermal camera:

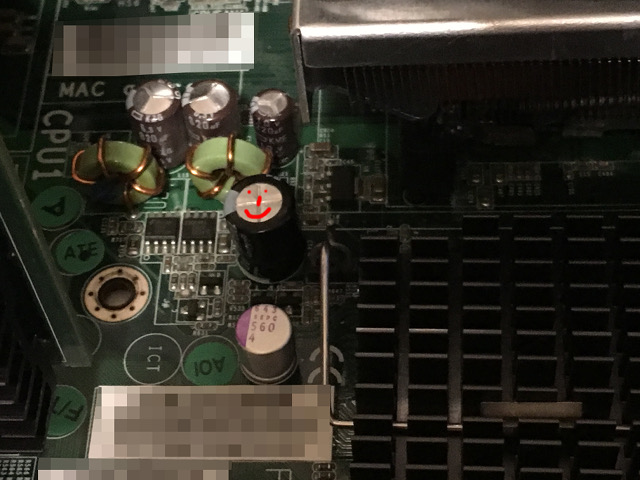

And, unsurprisingly, we find a bulging and slightly-leaky electrolytic near the hot (~80C, if running on a desk, 70C or so in well-ventilated case) northbridge:

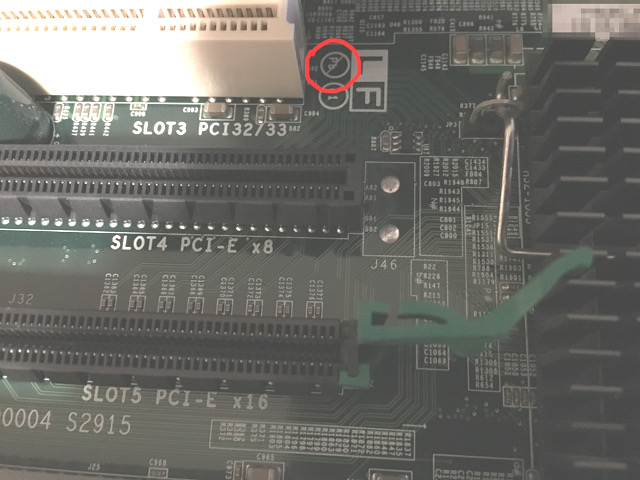

And another, similarly-sad one near the PCI-E slot where the video card was mounted:

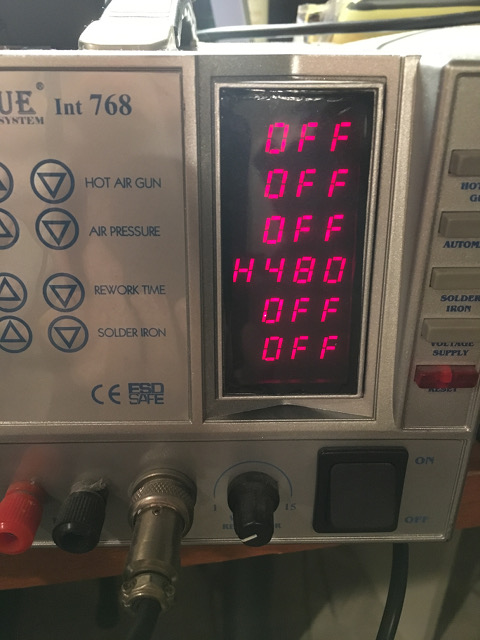

Now, this board is a vintage one, but unfortunately the lead-free solder scam was already in full swing at the time it was made:

And so what would otherwise have been a kindergarten-level repair job -- desoldering and replacing two large capacitors -- turns into a somewhat tricky and quite time-consuming exercise.

Even setting the iron to its maximum temperature (~250C):

... I found that the solder on the leads would not visibly begin to melt at all !

The melting point of Pb-free solder is considerably higher (how much higher -- varies, by particular composition) than of traditional alloys, and a commonplace adjustable soldering iron simply will not work. (And if you were to use a specially-made, hotter iron, you would quite possibly damage the surrounding tracks on the PCB.)

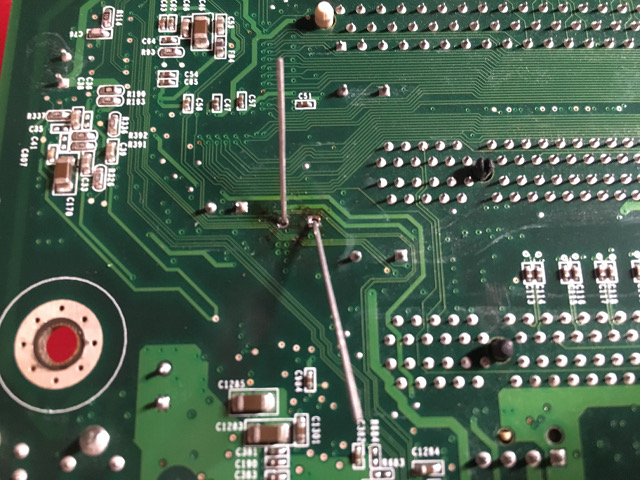

So now let's try a cheap but effective pill against the Eurocrat idiocy. We take a tube of good, old-fashioned pre-ban leaded solder, some wick, new capacitors:

Now add leaded solder, repeatedly, then wick it away. Again, and again. We end up slowly adding lead to the alloy until the melting point is manageable. It took me four shots of this, per capacitor leg, before either of the two sad caps would budge.

Now it is possible to install the new ones:

And we're back in business! Here's to another 11 years, old friend.

So,this isn't immediately relevant to the topic at hand. However, due to the whole purpose of using these CPUs fo LinuxBIOS/Libreboot/Coreboot, this is likely to be of interest: 'UPDATE: Coreboot/Libreboot on AMD has ‘CEO Level Attention’ and AMD is investigating how to go about support. Contacting AMD is having an impact!! Don’t give up/forget!' from reddit: https://www.reddit.com/r/linux/comments/5xvn4i/update_corebootlibreboot_on_amd_has_ceo_level/

2+ years later, this vapor -- unsurprisingly -- remains vapor. I.e. a typical case of "We did it, Reddit!"(tm)(r).